| Carbon tow; carbon fabric, chopped carbon fibers; milled carbon fibers, carbon veil; carbon powders; |

||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon fibers are made by converting Polyacrylonitrile fibers under heat and pressure into high strength, high modulus carbon fibers. These carbon fiber are then further processed and converted into:

Carbon fibres inherently are high in tensile and flexural strength, tensile and flexural modulus, conductive, inert to most chemicals, light weight, and as such, they are widely used in the following application: Archery Equipment; Aircraft parts; Artificial limb; Bridges; Conductive Floors and Walls; CNG fuel tank; Decorative parts; Golf shafts; Instrument cases; speed boat and Yacht; Process Rollers; Rackets; Race car; Structural Strengthening; Ships component; |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

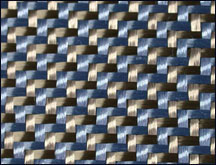

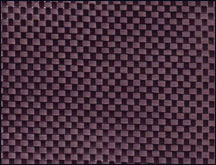

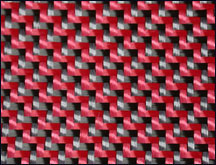

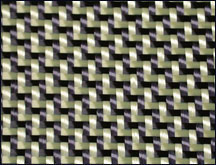

| Carbon Fabric and Carbon Kevlar Fabric | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||

For more information , contact us@ info@polymertec.com |

||||||||||||||||||||||||||||||||||||||||||||||||||

44 Tech Park Crescent Singapore 638095 Tel: (65) 6863 8225 Fax: (65) 6863 8219

Website: www.polymertec.com

| Home | Trade Name | Product List | Enquiry | ![]() | Web Links |

| Web Links |